Overhauling

When any machine runs, parts rub, friction occurs, and wear results. Keeping clocks lubricated and clean will minimize the wear. Clocks exposed to smoke (mantels are over fireplaces, after all,) blowing grit, and other environmental factors will suffer increased wear. Eventually, the clock will wear to the point that the increased friction prevents it from operating normally.

The most common clock wear problems are worn pivot holes, grooved pivots, worn escape pallets, and broken or set mainsprings.

The most common clock wear problems are worn pivot holes, grooved pivots, worn escape pallets, and broken or set mainsprings.

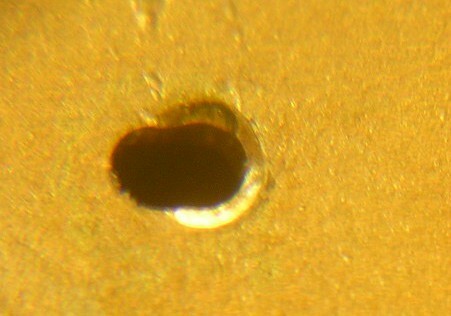

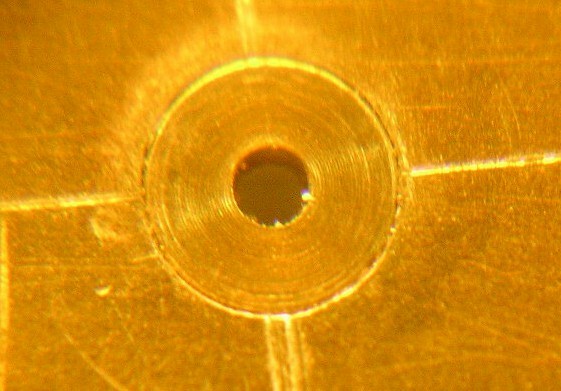

Worn Pivot Holes

Dust can get trapped in the clock oil and can act like a grinding compound. Eventually the pivot hole becomes elongated and allows the wheels to slip out of alignment. The teeth of properly aligned gears roll across each other. When wear allows gears to slip out of alignment, the teeth don’t roll so much as they slide across each other. This significantly increases the friction in the movement. The rough surface of a worn pivot acts like a file wearing the pivot hole out of round. A bushing returns the hole to the proper shape and location. (The scratches mark the center of the original hole.)

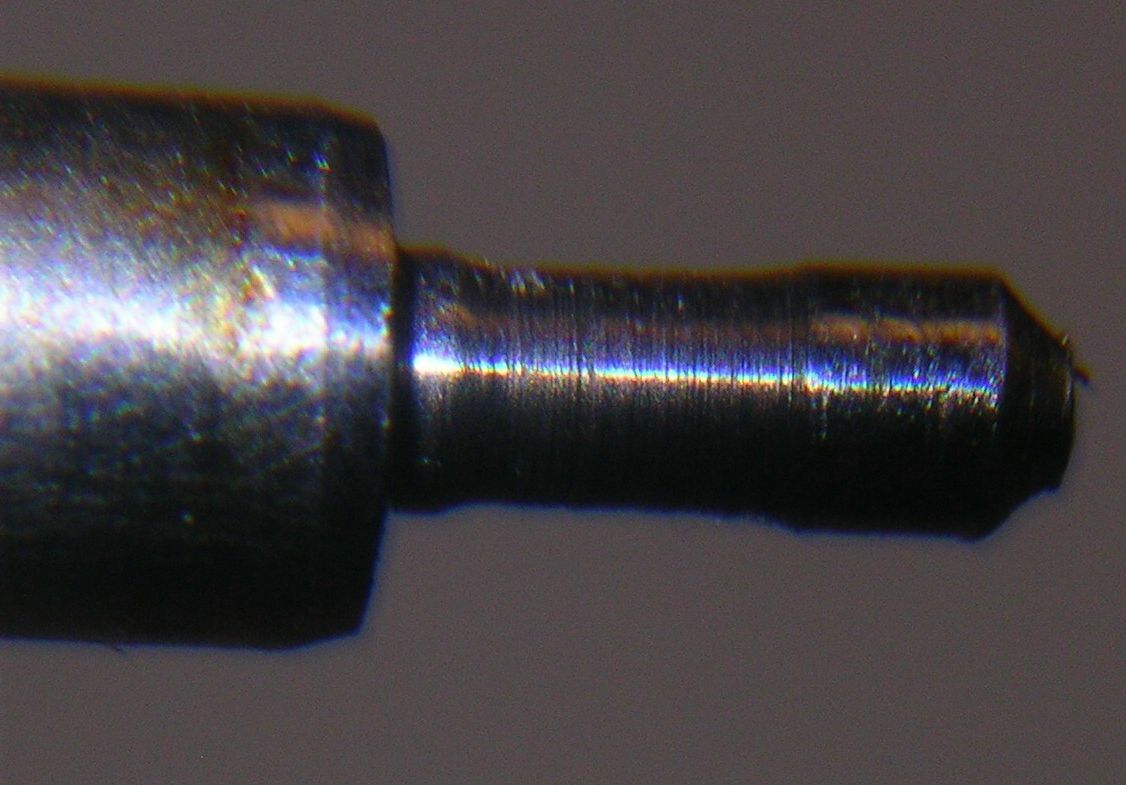

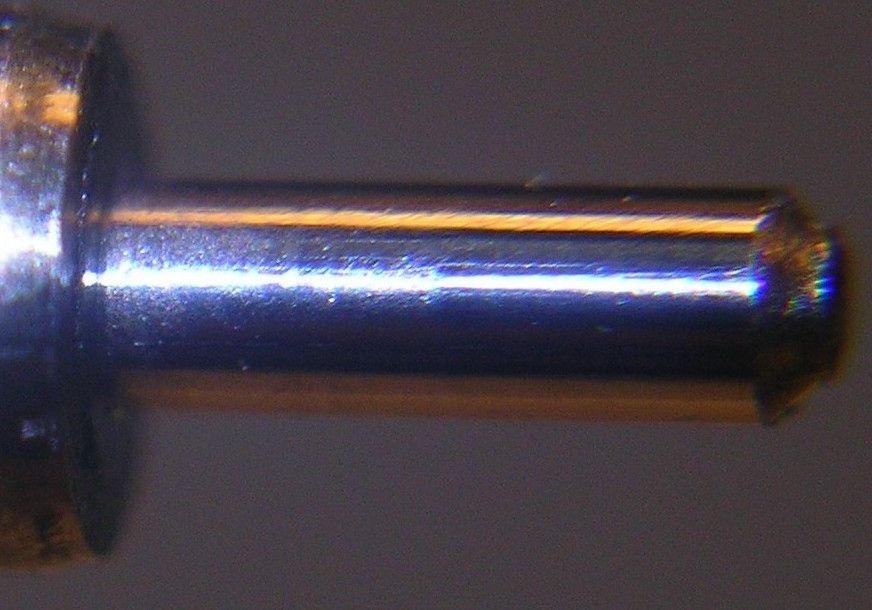

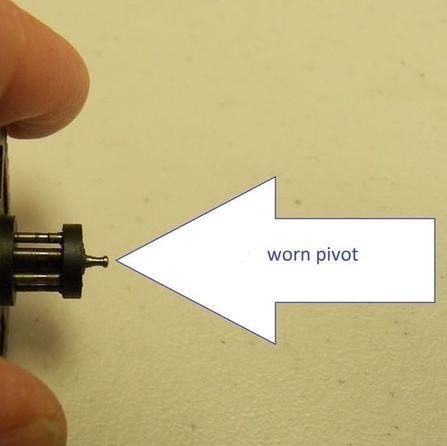

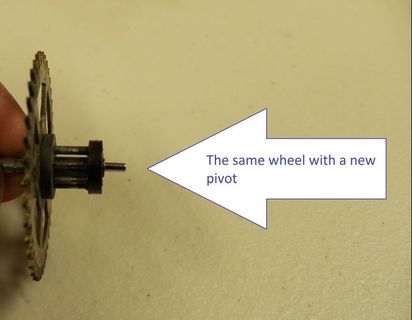

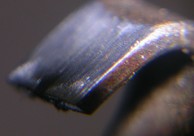

Grooved Pivots

The grit that attacks the pivot holes can also carve grooves in the pivots. If the grooves are not too deep, the grooves can be burnished and polished out.

If the diameter of the pivot would become too narrow by polishing it, then the pivot must be removed from the wheel, a hole drilled and a new pivot inserted to replace the old one.

Worn pallets

Other parts can also become worn. The pallets convert the circular motion of the escape wheel into the back and forth motion of the pendulum. Where the teeth of the escape wheel hit the pallets, a groove may be worn into the pallet surfaces. The groove may be polished out, or if possible, the escape wheel can be moved slightly to hit an unworn portion of the pallets.

Tired or Damaged Mainsprings

Mainsprings supply power to the hands, pendulum, hour stike, and chimes. Springs can become "set." When this happens, the maximum diameter that the spring can expand to is reduced. The spring on the left is set. Its maximum diameter is only about four inches. Compare that to the spring on the right that has a diameter of 10 inches. Set mainsprings must be replaced. All mainsprings must be inspected for fractures, rust and other problems.